How Can 3D Scanning Speed Up Quality Inspection in Plastic Injection Molding Industry?

The Challenges

Nowadays, our manufacturing industry can produce plastic parts at very large scale and high quality. However, the quality of injection-molded plastic parts is influenced by multiple factors. From the injection mold itself to the various processing parameters, and the ratio of plastic materials used, etc., even a small error can lead to quality issues in the whole high-volume, mass-production process.

For example, plastic manufacturers usually have concerns about mold platen deflection. These deflections can happen during high pressure buildup and transmit into molds, weakening the mold construction and affecting finished parts quality. Conducting strict monitoring of mold deflection is essential, especially for complex parts with tight tolerances. Verifying dimensions on parts to track mold deflection can help the engineers to determine the mold’s qualification status in time. Delays in mold verification and performance qualification will influence the whole cycle of products assembly, delivery, and sales.

However, with conventional tactile measurement tools, the injection mold and plastic parts are usually measured with limited measuring points, leaving large areas unchecked; And plastic parts are produced with more complex geometries such as deep holes, pockets, and angled edges, which are hard to reach by conventional tools; Meanwhile, direct decisions cannot be derived as problematic areas and cannot be identified immediately; At last, due to material properties, plastic parts are very easy to be deformed even with little pressure on the surface, which makes them hard to be measured precisely. Thus, a fast, efficient and non-contact measuring system is highly in need to accelerate the inspection process in the plastic injection molding industry.

Solution

Responding to the challenges above, ZG 3D laser scanner is the top-rated non-contact solution for this kind of inspection. Thanks to triangulation technology, which enables ZG 3D laser scanners to capture the most accurate and repeatable measuring data without touching the mold and plastic parts; With Standard/ Single Line/ Fine scanning modes, ZG 3D scanners can deliver full-field measuring data in a short time. Even the smallest details can be taken for accurate and realistic evaluation, for example, the correction values for the mold geometry, and the machine and processing parameters; Besides, the scan data of multiple parts can also be used for production control and trend analysis to minimize scrap and rework.

How Can ZG 3D Scanners Speed Up Inspection in Plastic Injection Molding Industry?

Mold Inspection

The molds used for producing injection-molded parts are often built from modified CAD data. These modifications include the combination of uniform and nonuniform shrink factors, adding of draft angles, parting lines, etc. Best practical experience is also incorporated to reduce the warping and twisting of the part. Thus plastic Injection molds need to be maintained strictly on regular basis for essential refurbishing, so that they can keep performing at the dimensions and accuracy as originally designed.

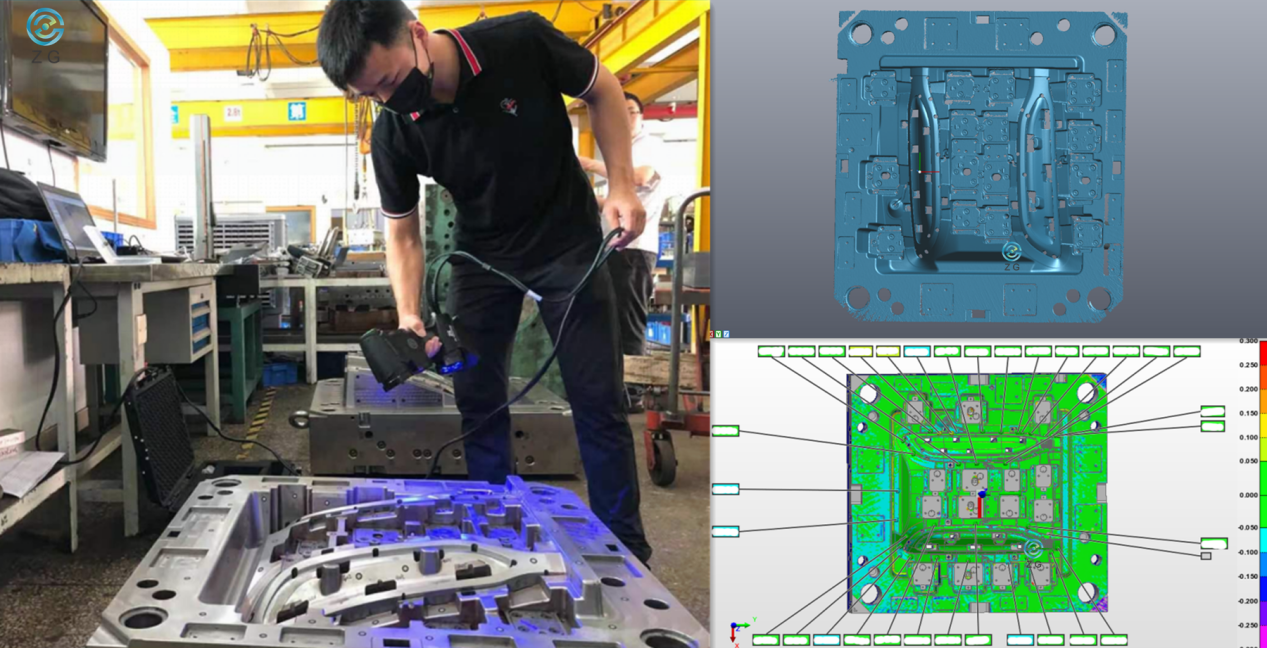

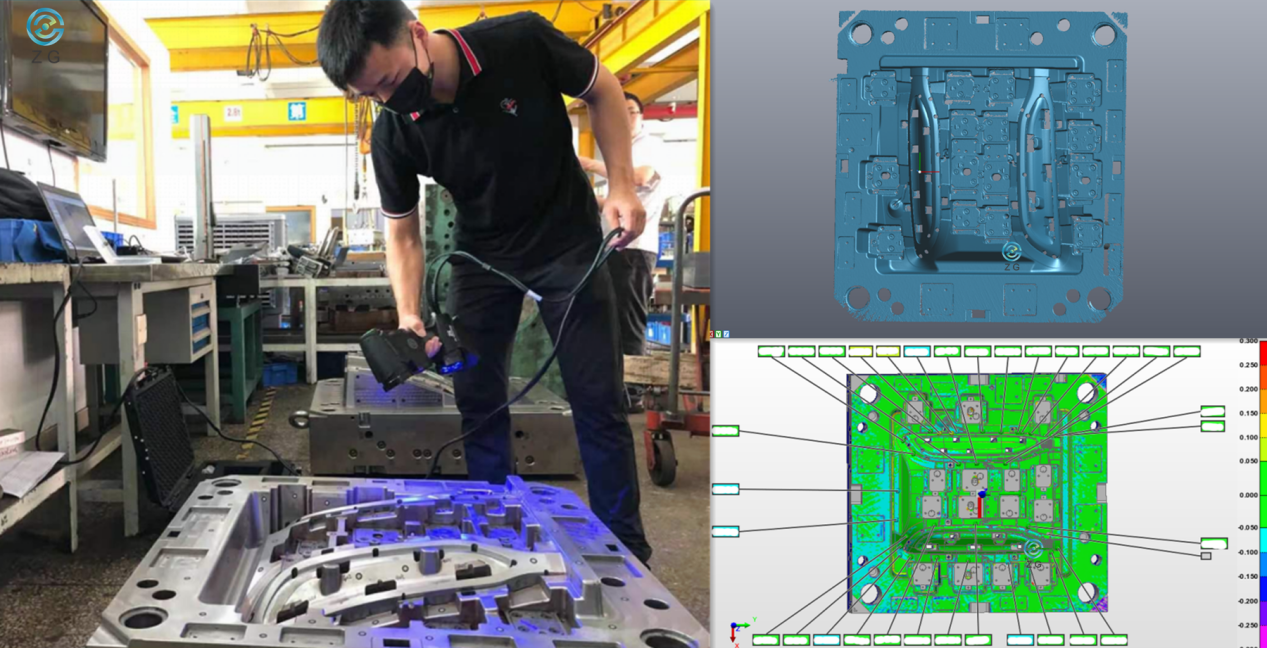

By adopting multi-mode, versatile metrology-grade 3D scanner -- AtlaScan which equips 26 blue laser lines for rapid scanning, extra single blue laser line for deep-hole & pocket scanning, extra 5 parallel blue laser line for fine-details scanning, and patented hole flash capture technology, we can scan the injection mold fast and accurately. With the color map inspection report, the engineers can know if the mold needs refurbishing or not clearly, which can not only save time but also reduce the inspection costs compared with manual measurements.

Versatile metrology-grade 3D scanner -- AtlaScan for Mold Inspection

First Article Inspection And Quality Control

The first part coming out from an injection mold is the critical test of the machining process and the mold itself. First article inspection (FAI) is a process of carefully measuring the first part for qualification evaluation, in both shape and dimensions, to the original CAD model. In the plastic injection molding industry, any deviation of injection-molded plastic components from the original design can affect the assembly, performance, and quality of the final product. This makes first article inspection (FAI) an essential step when producing injection plastic parts.

Meanwhile, even a company has an approved first article that is perfect and they go ahead with mass production based on that, but find that during the process something has gone wrong and all pieces are unqualified. It does happen in the best factories, which means only FAI is not enough, quality control of finished parts should also be strictly conducted. In the past, this process can involve multiple pieces of measurement tools and take dozens, even hundreds of hours. With ZG 3D laser scanners, the time is shortened to hours and minutes.

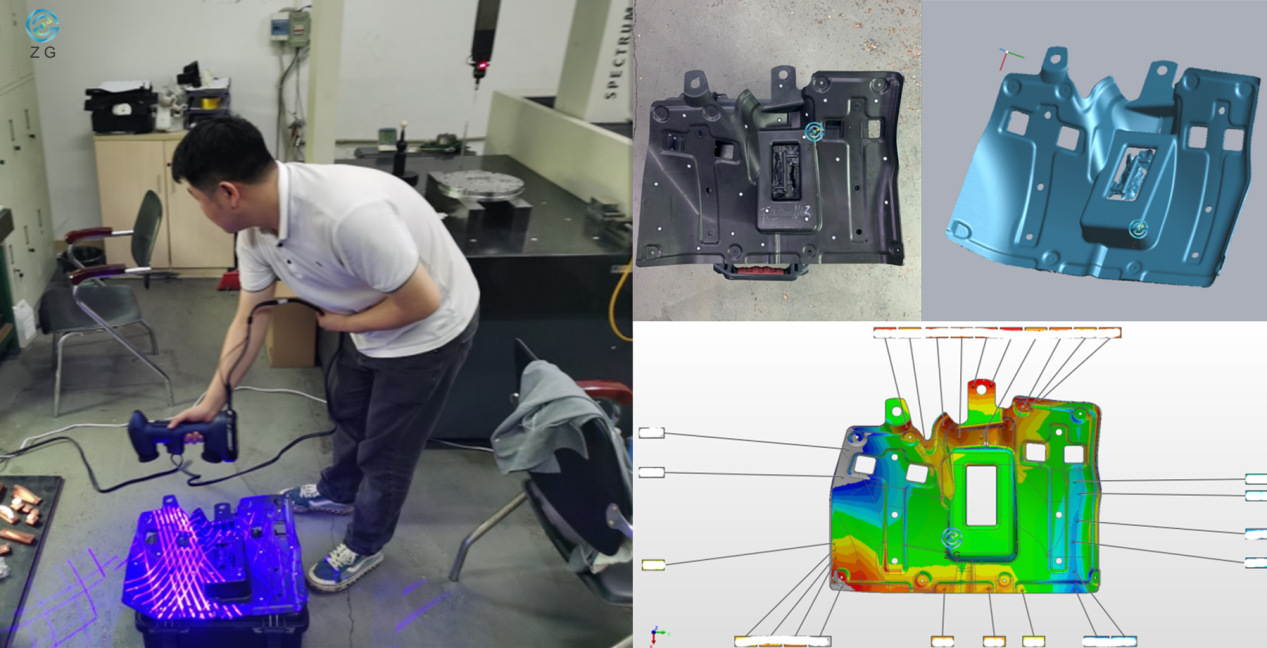

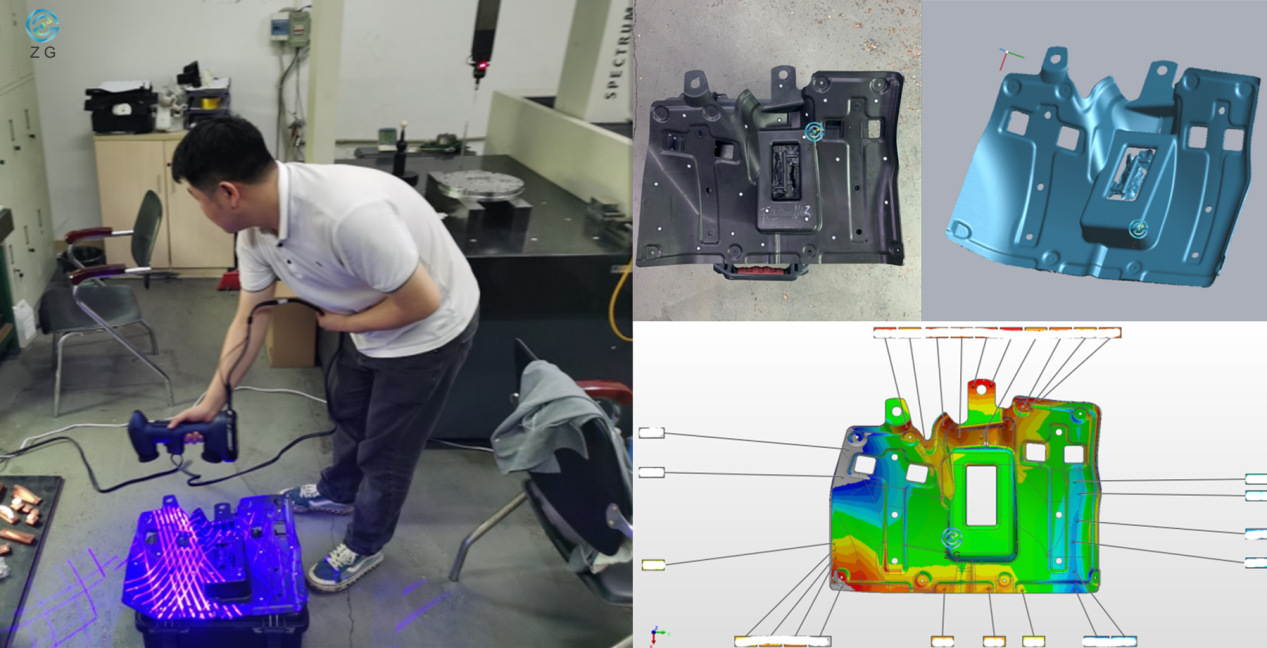

By adopting smart handheld blue laser 3D scanner--RigelScan Elite , regardless of whether the plastic part is black or white, we can scan directly without spraying agent and physical contact for First Article Inspection(FAI). What's more, only the first article needs manual operation for the entire scanning & inspection process; For the rest parts in mass production, operations such as alignment of scan data with the CAD model, dimensional inspection, and report output can be performed automatically.

Smart Handheld Blue Laser 3D scanner--RigelScan Elite for FAI

As the scan data and color map inspection report can be stored and reloaded easily, wear and changes in the production process are easy to be verified and controlled. Thus, the 3D data of the first article and finished products allows the inspectors not only to verify each process reliably, but also monitor different production processes to secure the quality of a plastic part over the whole life cycle.

Conclusion

An increasing number of companies are adopting ZG 3D laser scanners in their measuring departments, not only to achieve a better measurement accuracy, but to guarantee a comprehensive evaluation of the whole production process by full-field component analysis. With quick inspection and measurement reports, ZG 3D laser scanners can help plastic parts manufacturers to save hundreds of hours during mold making, mold tryout, first article approval and finished parts quality control, etc.s, which frees the engineers' professional resources, maximizes accuracy, reduces the number of mold remakes, and helps shorten the time to market. In all these ways, ZG 3D laser scanners can do what no other system can for the injection molding industry.

Besides the high quality 3D laser scanners, professional training sessions are available as well as tutorial-based courses like videos and detailed user manuals for ZG customers. For ZG Technology, innovation never ceases, so do the quality and customer services.