HyperScan 3D Software is a free and versatile software designed to use with Optical Tracking 3D Laser Scanners and Portable CMM Probe from ZG Technology Co., Ltd. In addition, HyperScan 3D Software is compatible with wireless module ZGFreeBox-S & ZGFreeBox-T, realizing the wireless scanning of ZG Optical Tracking 3D Laser Scanners.

With the features of easy to learn, fast processing speed and versatile functions in the toolbox, HyperScan 3D Software can support high speed 3D scanning with and without markers on object surface, scan data editing, optimization, GD&T measuring, color mapping, protable CMM probing as well as inspection report generating.

The 3D scan&probing data can be used for quality inspection, reverse engineering, 3D visualization, 3D printing etc., which cover the full product life cycle from concept design, mold design, mold MRO to FAI (First Ariticle Inspection) and inspection of mass production parts, benefiting the industries of automotive manufacturing, aerospace, military, medical, energy, and hydropower etc.

Easy to Learn

Intuitive software interface, easy to learn and use

Help the users to focus attention on work

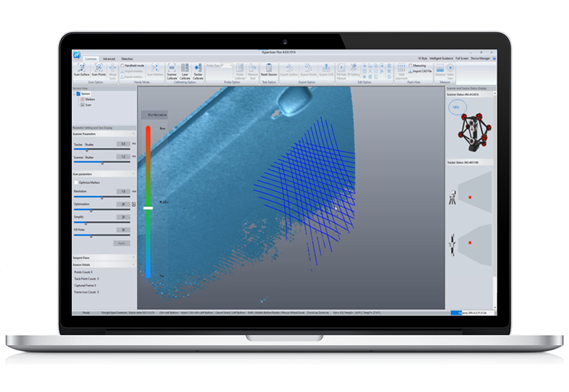

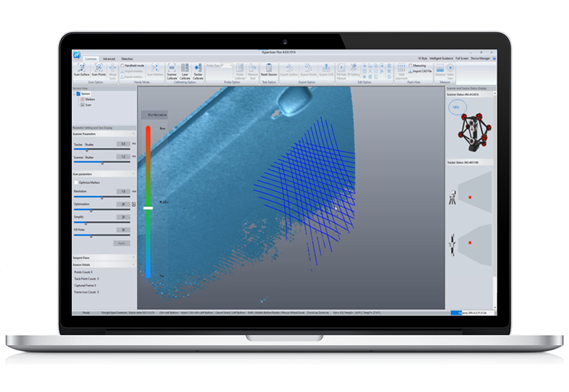

Real Time Display

Real time display of the scanner's tracking status with the optical tracker

Distance indicator bar guiding the best scanning distance

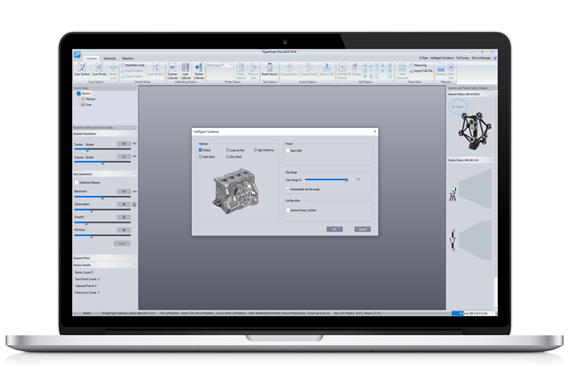

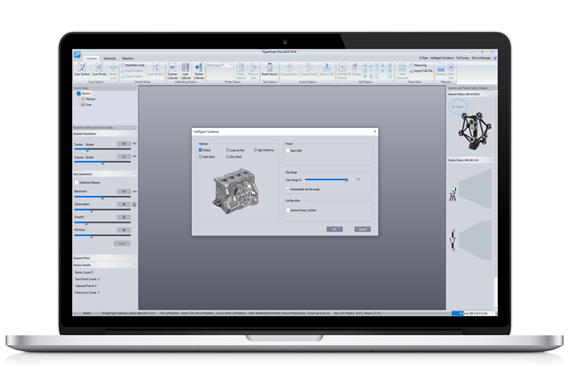

Intelligent Guidance Module

All scanning parameter can be set automatically with one simple click

Even new users can deal with black, shiny surfaces easily

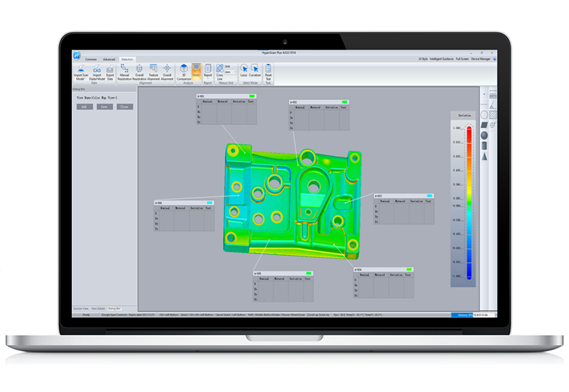

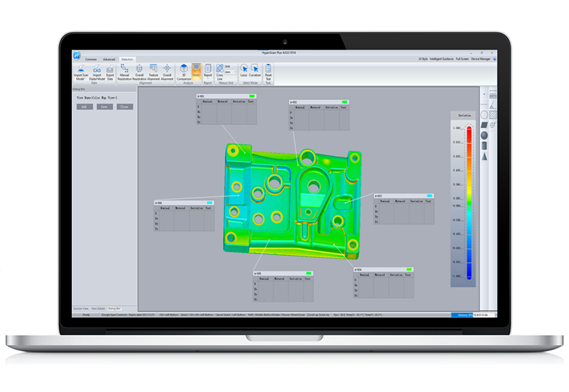

3D Measurement & Inspection

To optimize high quality scan data for dimension, GD & T measurement; Import CAD model for 3D inspection without leaving the software

To generate inspection report for data archiving