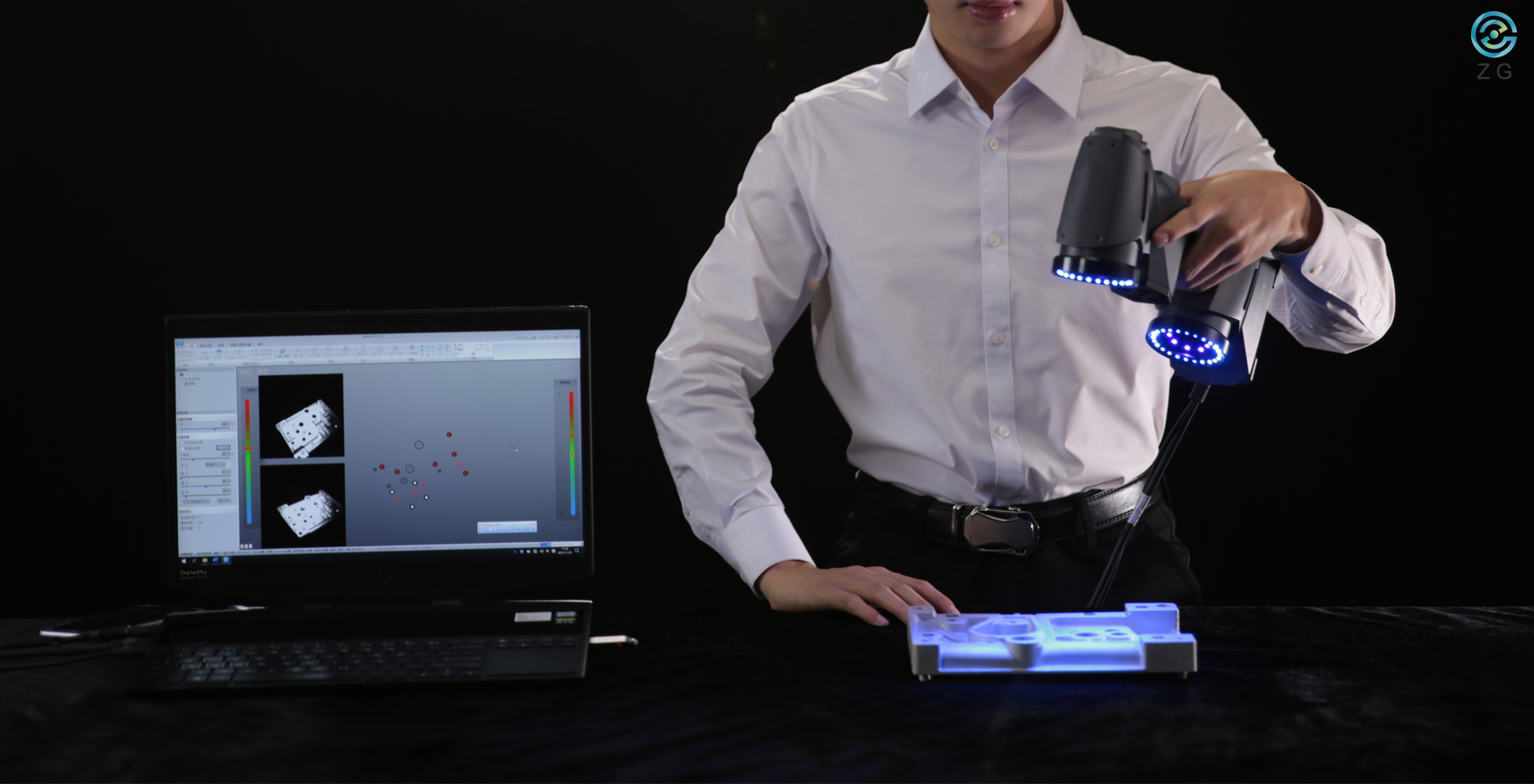

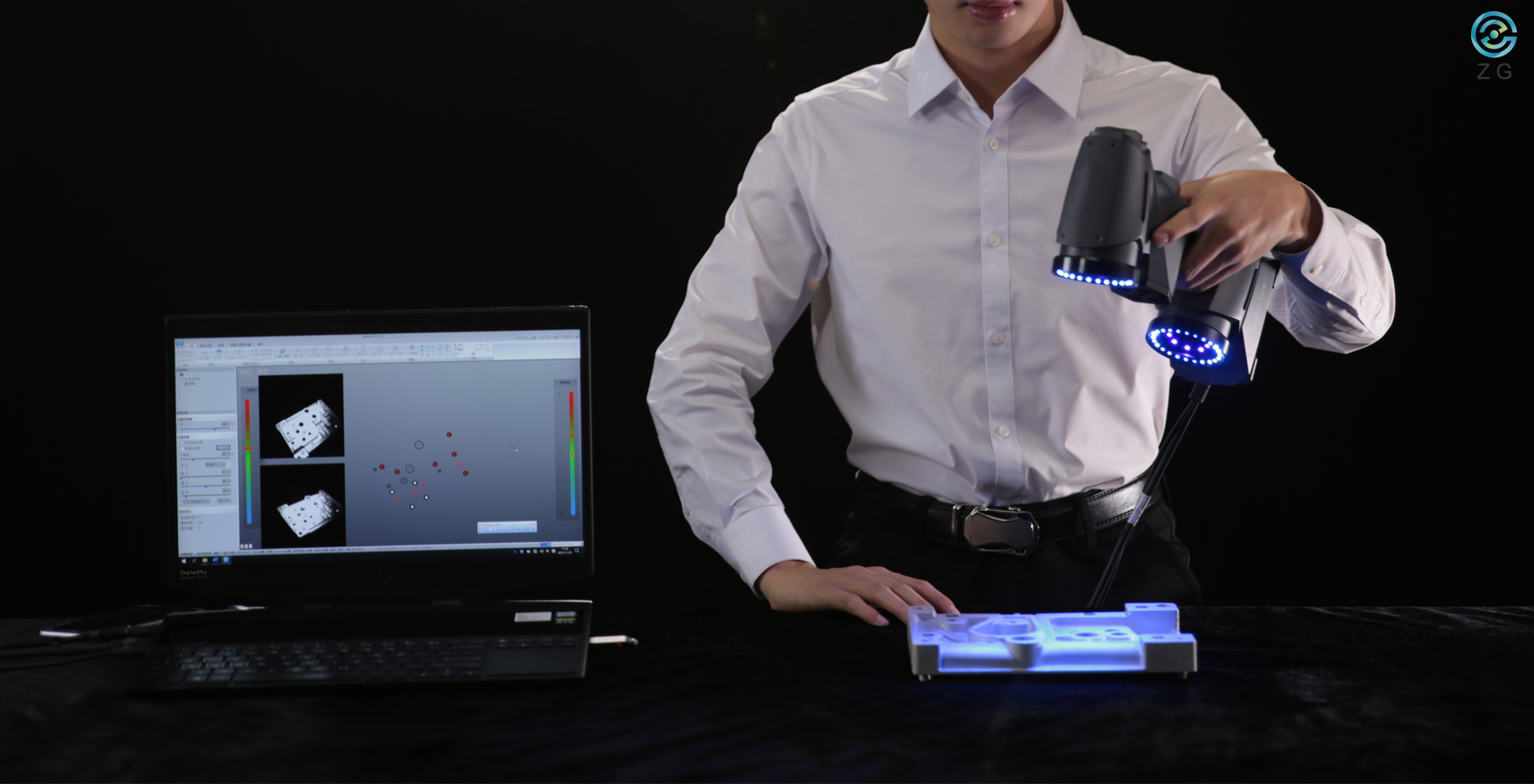

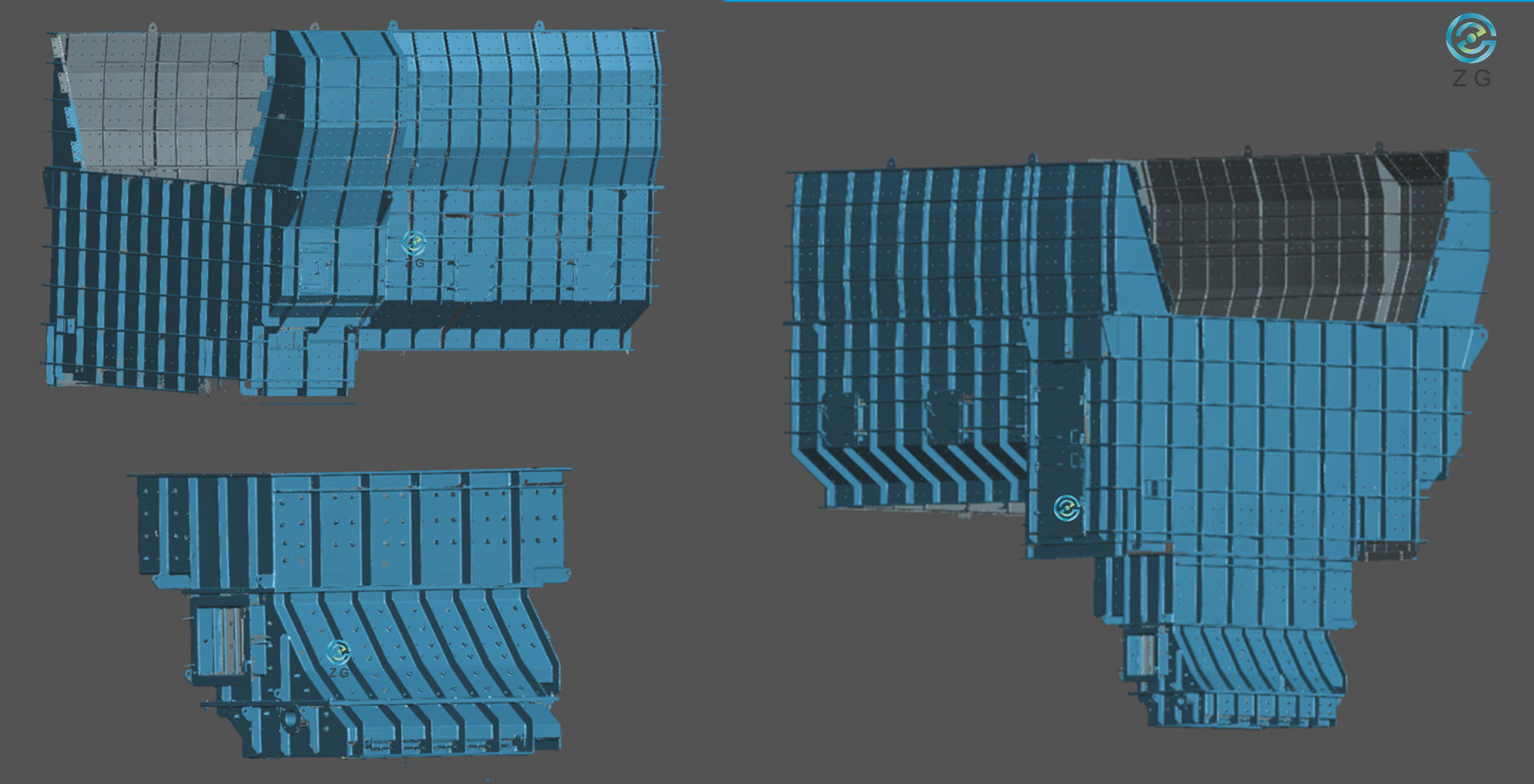

Driven by the trend of digital revolution, using traditional contact methods to inspect large-volume parts cannot ensure higher product quality and reduce production cycle time. With advanced laser scanning technologies, ZG provides professional and complete 3D scanning solutions which dramatically reduce the time engineers spend to inspect defects, regardless of size, shape and surface condition of the object. In this case, we adopt HyperScan, the smart optical tracking 3D scanner, and PhotoShot Max, the wireless photogrammetry system, to inspect a large weldment.

Read More

Most economies around the world are facing unprecedented energy crisis in recent years caused by a variety of factors, such as climate change and the shortage of fossil fuels. With global energy demand increasing rapidly, more and more countries are turning to clean energy. As one of the main sources of clean energy, wind power has been widely used to produce electricity. Wind turbines use blades to convert the wind’s kinetic energy into the electricity we use to power our homes. Nowadays, to generate more cost-effective wind energy, the size of wind turbines has grown, both in height and blade lengths, which also poses new challenges to the manufacturing, quality control, and operation of wind turbine blades. Therefore, to optimize the work performance of large-scale wind turbine blades, 3D laser scanners have become the smart measurement solutions to overcome these obstacles.

Read More

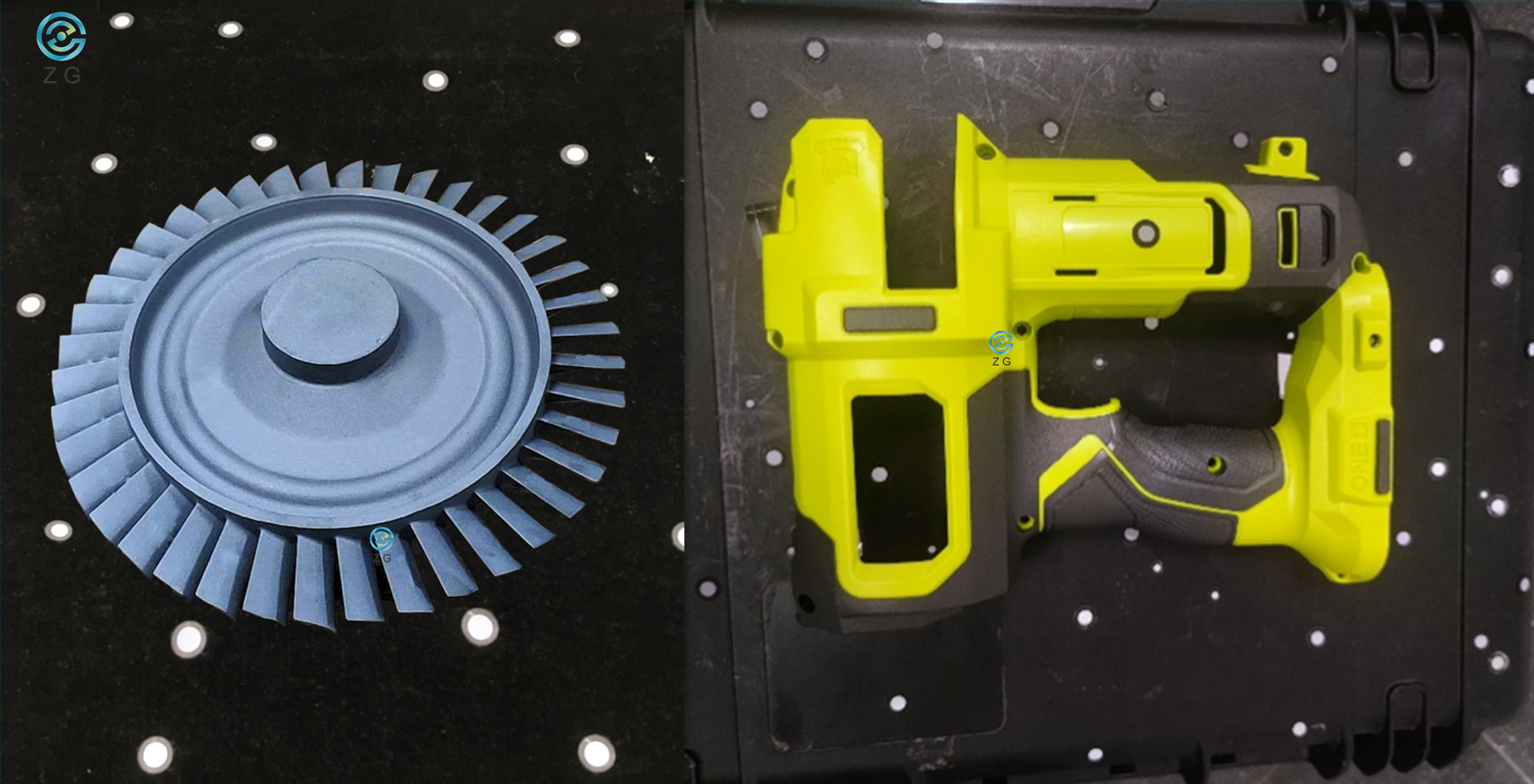

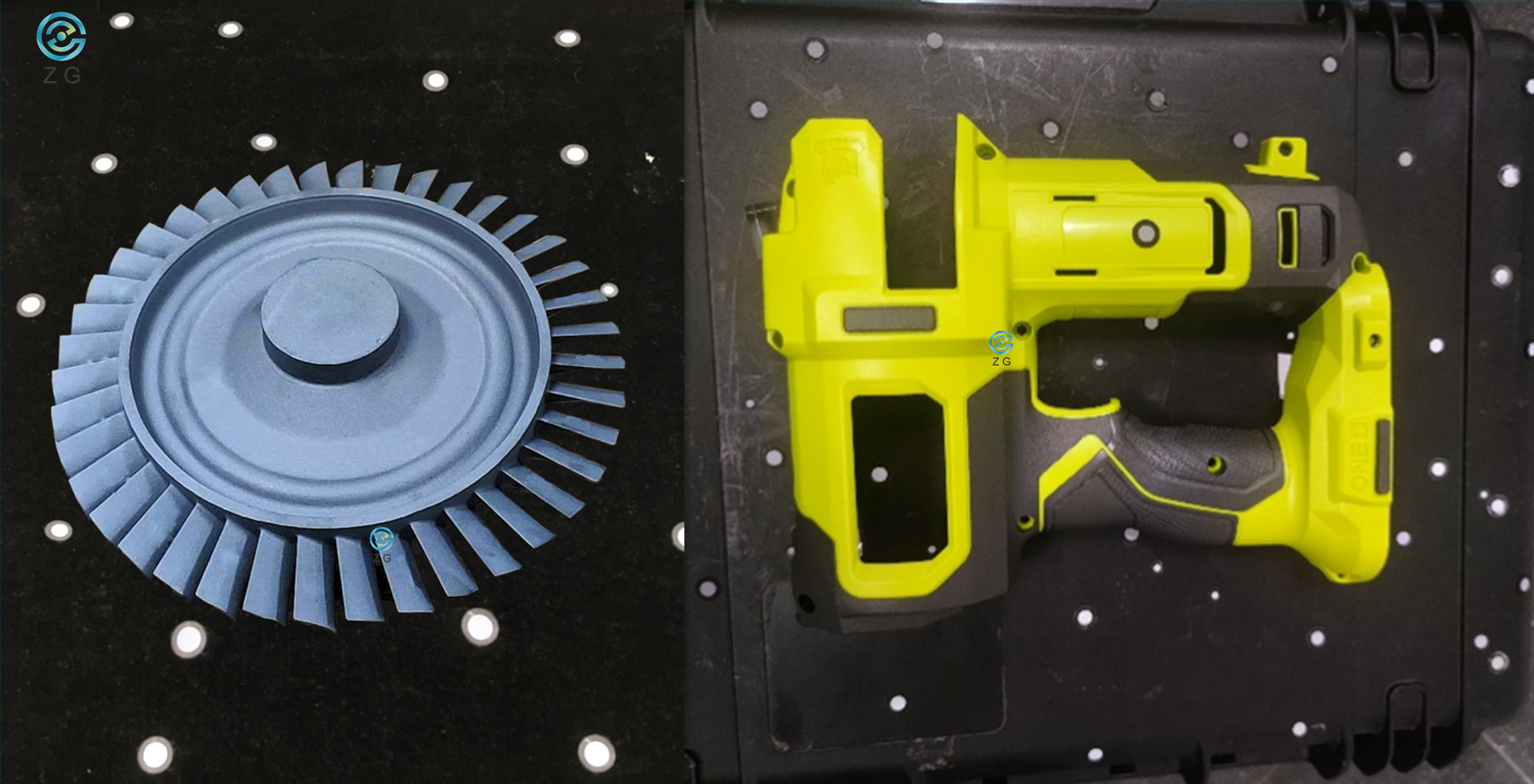

Nowadays, our manufacturing industry can produce plastic parts at very large scale and high quality. However, the quality of injection-molded plastic parts is influenced by multiple factors. From the injection mold itself to the various processing parameters, and the ratio of plastic materials used, etc., even a small error can lead to quality issues in the whole high-volume, mass-production process.

Read More

Whether you’re buying your first 3D scanner or upgrading an existing one, there are many factors to consider before choosing the right 3D scanner for your application. In this article, we will discuss about the most important things to consider before making the decision and help you to choose the most suitable 3D scanner.

Read More

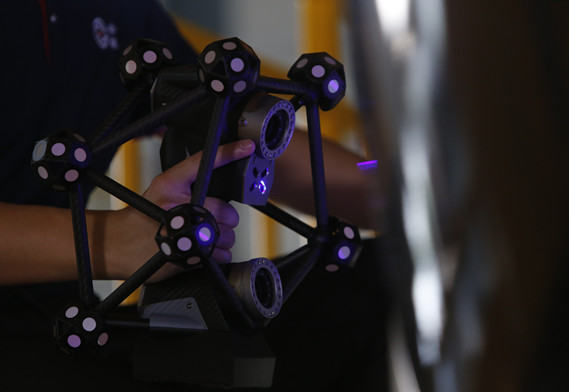

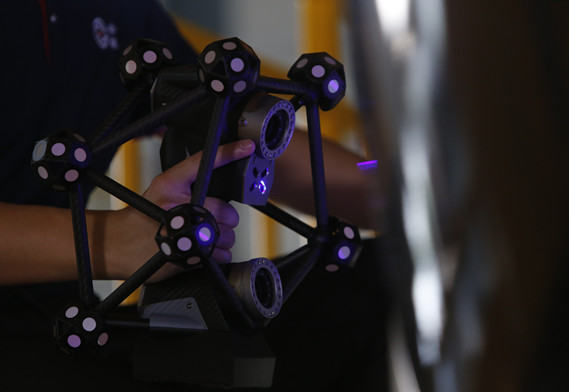

Table of Contents: What Are Reflective Markers? Why Are Reflective Markers Needed in 3D Scanning? Reflective Markers Placement Guidance How Can ZG 3D Laser Scanner Help Quality Inspection When Scanning with Markers? Marker-Free Solutions The Conclusion

Read More

Table of Contents:l What is reverse engineering?l What is the reverse engineering process?l What are the uses of reverse engineering?l How can ZG’s 3D scanners speed up reverse engineering l More to expect. What is reverse engineering? Reverse engineering (also known as backwards engineering or bac

Read More

Sanxingdui is an archaeological site and a major Bronze Age culture in modern Guanghan, Sichuan, China. Largely discovered in 1986, following a preliminary finding in 1927, archaeologists excavated artifacts that radiocarbon dating placed in the 12th–11th centuries BC. The type site for the Sanxingdui culture that produced these artifacts, archeologists have identified the locale with the ancient kingdom of Shu. The artifacts are displayed in the Sanxingdui Museum located near the city of Guanghan. --- Wikipedia

Read More

A pavement milling machine is an efficient pavement maintenance equipment, which can mill and grind pavement in a large or partial area and recycle old materials, then lay new materials for pavement resurfacing. It can also roughen up pavement with a low friction coefficient to obtain higher pavemen

Read More

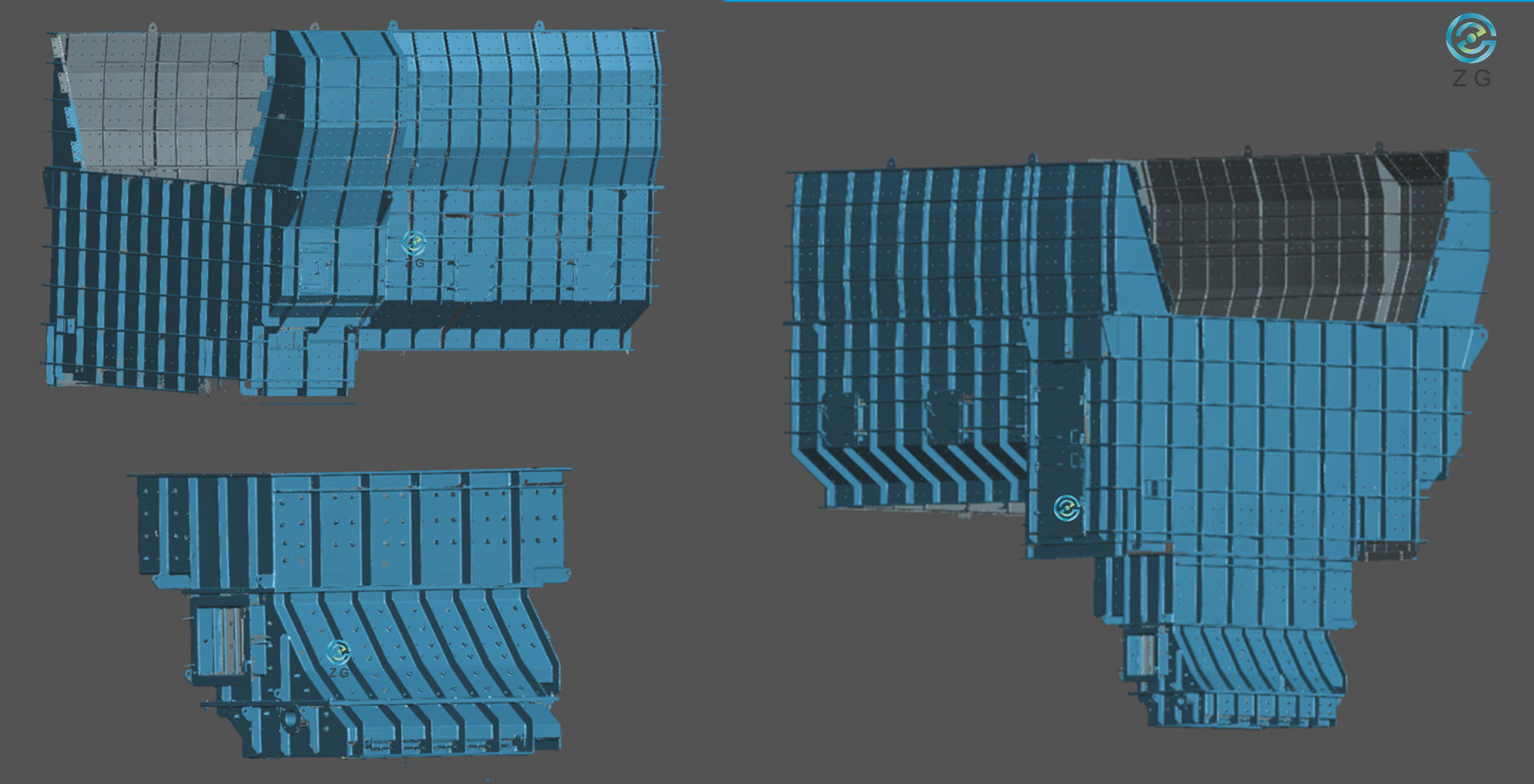

BackstoryHeavy industries and mining usually mean difficult conditions and oversized equipment, quality inspection plays a vital role to guarantee the equipment’s stability and durability under harsh working environments. Considering the equipment size and complexity, it’s usually the measurement to

Read More

Why a 3D Scanner Is Needed in Large Casting’s 3D Inspection? Common methods for casting’s 3D inspectionTo meet casting part dimensional requirements such as tolerances, a metal casting facility can check the dimensional accuracy of parts manually or with coordinate measuring machine (CMM). Manual i

Read More